|

|

|

PROCESS AUTOMATION FOR THE FOOD, BEVERAGE, PACKAGING AND GLASS INDUSTRY.

Bbull process automation for the beverage, food, packaging and glass industry in the areas of detection, rejection and sorting of bottles, cans, jars, crates, cartons, trays, six packs and kegs.

Quality control and increased productivity in a filing line by integrating inspection systems Line optimization with project specific distribution and conveying technology .Production of palletizing and packaging machinery as well as crate washing systems and robot technology. Maintenance, repair and optimizing of machinery and equipment. Project planning including turn key systems integration 24/7 hr technical support.

|

|

Glass. Pet, Cans, Cartons, Crates

|

|

Fill Level, Cap, Label and Foreign Body Inspection

|

|

|

|

|

Performed with pc-based inspection systems that monitor the production details with X-ray technology, camera based image processing, acoustic inspection or sensor technology . Based on integration and combination of different detection technologies their modular scaleable design guarantees quality assurance as well as line and process monitoring .

|

|

|

|

|

Label and barcode Inspection

|

|

|

|

|

Inspection does not include the application of the label, but also the orientation of the bottle in advance.

Defects, such as dog ears wrinkes as well as traditional defects, are detected reliably. The single or multi camera inspection systems can be mounted in the labeller or at the conveyor after the labeller for non-oriented containers. These systems can be designed with colour or black/white cameras to achieve the highest production speeds and highest quality of inspection. A user optimized interface (HMI) in combination with the line synchronization modules will provide a smooth operating production line.

|

|

|

|

|

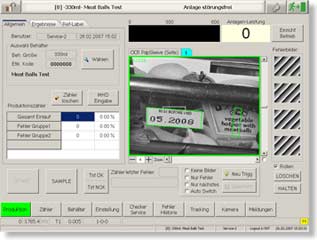

Print & Date Inspection

|

|

|

|

|

The windows -based image processing software ''IMAGE'' uses neuronal networks for the reading of best-before-dates or batch numbers and avoids faulty prints, wrong content or faulty input from the operators.

The Hardware and software components are combined and scaleable and allow tracking of the faulty containers to the source. The application will determine the type of technology that will be used such as fire-wire or line cameras.

|

|

|

|

|